Korky fill valves are essential for efficient toilet tank operation, controlling water flow and preventing leaks. Replacing or adjusting them can resolve common issues like constant running or poor flushing. Proper installation and maintenance ensure optimal performance, saving water and reducing utility bills. Follow these step-by-step guides to install, adjust, and troubleshoot your Korky fill valve effectively.

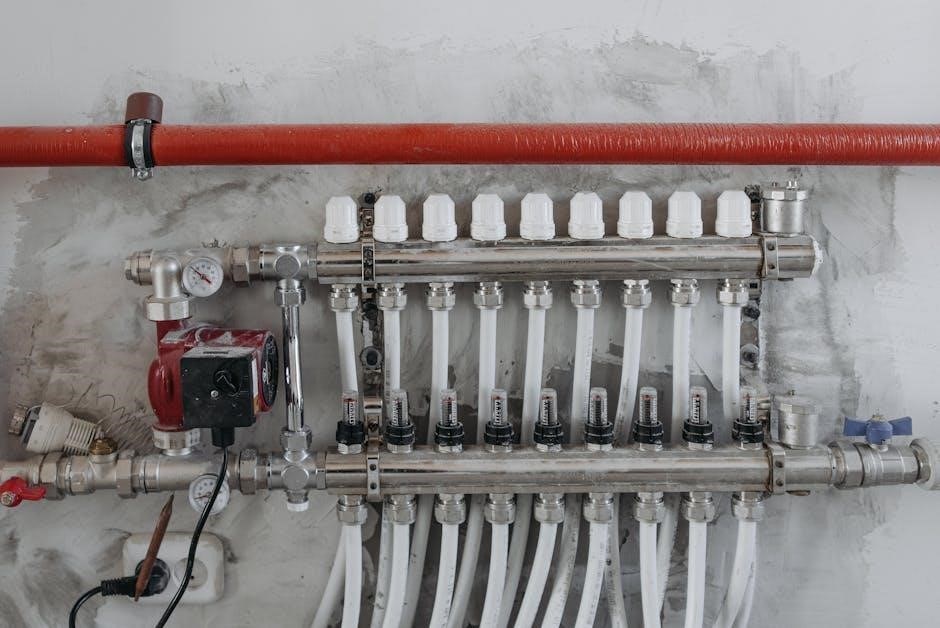

Overview of the Korky Fill Valve

The Korky fill valve is a versatile and durable component designed for efficient toilet tank operation. It features an internal float mechanism that regulates water flow, eliminating the need for external adjustments. Known for its universal compatibility, Korky fill valves fit most toilet models, including Toto toilets, making them a popular choice for homeowners. The QuietFILL technology ensures silent operation, while the twist-lock adjustment simplifies height customization. With a focus on longevity and performance, Korky fill valves are constructed to withstand regular use and provide reliable service. Their innovative design makes them easy to install and maintain, ensuring optimal water level control.

Why Replace or Adjust a Korky Fill Valve?

Replacing or adjusting a Korky fill valve is crucial to address issues like leaking, running toilets, and inefficient water usage. Over time, wear and tear can cause the valve to malfunction, leading to higher water bills and potential damage. Adjusting the float mechanism ensures the correct water level, preventing overflow or inadequate flushing. Regular maintenance and timely replacement of worn-out components can extend the lifespan of the toilet and enhance its performance. Addressing these issues promptly helps maintain a functional and water-efficient toilet system, saving both time and money in the long run;

Tools and Materials Needed

Essential tools include an adjustable wrench, pliers, and a sponge. Materials needed are a new Korky fill valve, overflow tube (if required), and a bucket for water drainage.

Essential Tools for Installation

An adjustable wrench is crucial for loosening nuts on the water supply line and fill valve. Pliers are needed for unhooking the fill valve from the flush valve. A sponge or towel helps remove excess water from the tank. A bucket is handy for draining water from the tank before starting work. Additionally, a screwdriver may be necessary for adjusting the float mechanism or accessing internal components. These tools ensure a smooth and efficient installation process for your Korky fill valve.

Recommended Materials for Proper Functionality

A new Korky fill valve is essential for optimal performance. Choose models like the QuietFill or Universal Toto fill valve for compatibility. Ensure the valve fits your toilet model for proper operation. Internal floats and serviceable parts enhance reliability. A lower overflow tube may be needed for code compliance. Adjust the fill valve height to match the flush valve overflow tube; Proper materials ensure efficient water flow and prevent leaks. Follow manufacturer guidelines for specific requirements. These recommendations guarantee long-term functionality and trouble-free operation of your Korky fill valve.

Step-by-Step Installation Guide

Turn off water supply, flush, and drain the tank. Disconnect the old fill valve, then install the new Korky valve, ensuring proper alignment and secure connection. Adjust the water level as needed and test functionality to ensure leaks are resolved and performance is optimized.

Removing the Old Fill Valve

Begin by turning off the water supply to the toilet. Flush the toilet to drain the tank, then use a sponge to remove any remaining water. Disconnect the water supply line from the old fill valve using an adjustable wrench. Locate the hook connecting the fill valve to the flush valve and use pliers to unhook it. Carefully lift the old fill valve out of the tank. If stubborn, gently rock it back and forth to dislodge it. Once removed, inspect the area for debris and clean it with a damp cloth before installing the new Korky fill valve.

Installing the New Korky Fill Valve

Insert the new Korky fill valve into the tank, ensuring it fits securely through the designated hole. Hand-tighten the mounting nut to hold it in place. Use an adjustable wrench to tighten the nut further, being careful not to over-tighten. Reattach the water supply line, tightening the nut by hand, then secure it with a wrench. Bend the float arm to adjust the water level as needed. Turn the water supply back on and flush the toilet to test the fill valve’s operation. Check for leaks around connections and ensure the water level is set correctly for optimal performance.

Adjusting the Water Level

Adjust the water level by bending the float arm up or down until the water reaches the desired height, typically 1/2 inch below the overflow tube.

Understanding the Float Mechanism

The Korky fill valve uses an internal float mechanism to regulate water levels in the toilet tank. As the water level drops during a flush, the float lowers, opening the valve to refill the tank; Once the water reaches the set level, the float rises, sealing the valve to prevent overflow. This mechanism is designed for precise control, ensuring efficient operation and preventing leaks. Unlike traditional ballcock systems, Korky’s internal float is less prone to wear and tear, offering smoother and quieter performance. Proper adjustment of the float arm is crucial for maintaining optimal water levels and functionality.

How to Adjust the Water Level for Optimal Performance

To adjust the water level, locate the twist-lock adjustment on the Korky fill valve. Turn the flat disc clockwise to lower the water level or counterclockwise to raise it. Ensure the water level mark on the valve is 1/2 inch below the top of the flush valve overflow tube. After adjusting, flush the toilet to test the water level. Proper adjustment prevents overflow and ensures efficient flushing. If the water level is too high, it may cause continuous running, while a low level can result in incomplete flushing. Adjusting the float arm height can also fine-tune the water level for optimal performance.

Troubleshooting Common Issues

Identify leaks by inspecting connections and seals. Adjust the float arm if it sticks or doesn’t shut off properly. Clean debris from the valve inlet to ensure smooth operation.

Identifying and Fixing Leaks

Leaks around the Korky fill valve often stem from worn-out seals or misaligned connections. Turn off the water supply and inspect the valve for water droplets; Tighten loose nuts or replace damaged gaskets; Adjust the float arm to ensure it moves smoothly without sticking. Clean debris from the valve inlet to prevent obstruction; If leaks persist, consider replacing the fill valve entirely. Regular maintenance and inspection can prevent future issues, ensuring optimal performance and water efficiency.

Resolving Problems with the Fill Valve Operation

If the Korky fill valve isn’t functioning correctly, check the float mechanism. Ensure it moves freely without obstructions. Adjust the float arm height to regulate water levels properly. Clean the valve inlet to remove debris that might block water flow. If the valve fails to shut off completely, inspect the seal inside the cap for wear or mineral buildup. Replace the seal if necessary. For persistent issues, consider replacing the entire fill valve. Proper adjustment and maintenance ensure smooth operation, preventing overflow and continuous running, and extending the valve’s lifespan.

Maintenance and Care Tips

Regularly clean the fill valve and float mechanism to ensure proper function. Inspect for mineral buildup and corrosion. Adjust water levels as needed to prevent overflow and conserve water.

Regular Cleaning and Inspection

Regular cleaning and inspection of your Korky fill valve are crucial for maintaining its performance. Start by turning off the water supply and flushing the toilet to drain the tank. Use a soft cloth or brush to remove mineral buildup and debris from the fill valve and surrounding areas. Inspect the float mechanism for proper alignment and adjust if necessary; Check the fill tube for blockages or cracks and replace it if damaged. Clean or replace the flapper or seal if leaks are present. Regular maintenance ensures smooth operation and prevents issues like constant running or low water pressure.

Long-Term Maintenance for Extended Lifespan

For long-term maintenance, periodically inspect the Korky fill valve’s internal components, such as the float and seal, to ensure proper function. Replace worn parts promptly to prevent leaks and inefficiency. Clean the valve regularly to remove mineral buildup, which can affect performance. Avoid using harsh chemicals, as they may damage the valve’s materials. Ensure the water level is correctly adjusted to prevent overfilling or insufficient water supply. Korky fill valves are designed for durability, but consistent care will extend their lifespan and maintain optimal performance over time.

Proper installation, adjustment, and maintenance of the Korky fill valve ensure efficient toilet operation, water savings, and improved flush performance. Follow the instructions for optimal results and longevity.

Final Checks and Ensuring Proper Function

After installing or adjusting your Korky fill valve, perform a final flush to ensure proper operation. Check the water level to confirm it aligns with the recommended height, typically 1/2 inch below the overflow tube. Inspect all connections for leaks, tightening any loose nuts if necessary. Verify that the fill valve shuts off completely when the tank is full. Test the flush valve operation to ensure smooth refilling and flushing. Regularly cleaning the fill valve and float mechanism will prevent mineral buildup and maintain optimal performance. Proper maintenance ensures longevity and efficient water usage.