Monobond Etch & Prime is a single-component ceramic primer that simplifies surface preparation by etching and silanizing glass-ceramic surfaces in one efficient step‚ enhancing bond strength and durability;

Overview of Monobond Etch and Prime

Monobond Etch & Prime is a revolutionary‚ single-component ceramic primer designed to condition glass-ceramic surfaces in one step. It combines etching and silanization‚ eliminating the need for hydrofluoric acid‚ making it safer and faster. This innovative solution ensures a strong‚ reliable bond between ceramic surfaces and luting composites‚ streamlining dental restoration processes. Its advanced formulation enhances surface reactivity‚ providing a durable and long-lasting bond‚ while its ease of use simplifies clinical workflows.

Importance of Ceramic Surface Conditioning in Dentistry

Ceramic surface conditioning is crucial for achieving optimal bond strength between dental restorations and luting composites. Proper conditioning ensures a strong‚ durable bond‚ minimizing the risk of restoration failure. It also enhances the compatibility of ceramic surfaces with adhesive materials‚ leading to better clinical outcomes. Effective conditioning like Monobond Etch & Prime streamlines the process‚ reducing the need for multiple steps and enhancing safety by eliminating toxic agents‚ thus improving both efficiency and patient satisfaction in dental procedures.

Composition and Properties

Monobond Etch & Prime contains ammonium polyfluoride for etching‚ silane methacrylate for bonding‚ and phosphoric acid‚ creating a strong‚ durable bond with ceramic surfaces.

Key Ingredients and Their Functions

Monobond Etch & Prime contains ammonium polyfluoride‚ which etches ceramic surfaces to create microretentions for better bonding. Silane methacrylate acts as a coupling agent‚ ensuring a strong bond between the ceramic and adhesive material. Phosphoric acid enhances etching efficiency and stabilizes the pH‚ promoting optimal surface preparation. Together‚ these ingredients ensure a reliable and durable bond‚ combining etching and silanization in a single step for efficient ceramic surface conditioning.

Role of Ammonium Polyfluoride and Silane Methacrylate

Ammonium polyfluoride plays a crucial role in etching ceramic surfaces‚ creating microretentions for improved bonding. It ensures proper surface roughness‚ enhancing the mechanical bond between the ceramic and adhesive material. Silane methacrylate‚ on the other hand‚ acts as a coupling agent‚ forming a chemical bond between the ceramic and the resin. Together‚ these components synergistically promote a strong‚ durable bond‚ eliminating the need for separate etching and silanization steps; Their combined action ensures efficient and reliable ceramic surface conditioning.

Instructions for Use

Apply Monobond Etch & Prime to the ceramic surface using a microbrush. Allow the product to react for 40 seconds‚ then rinse thoroughly with water and dry.

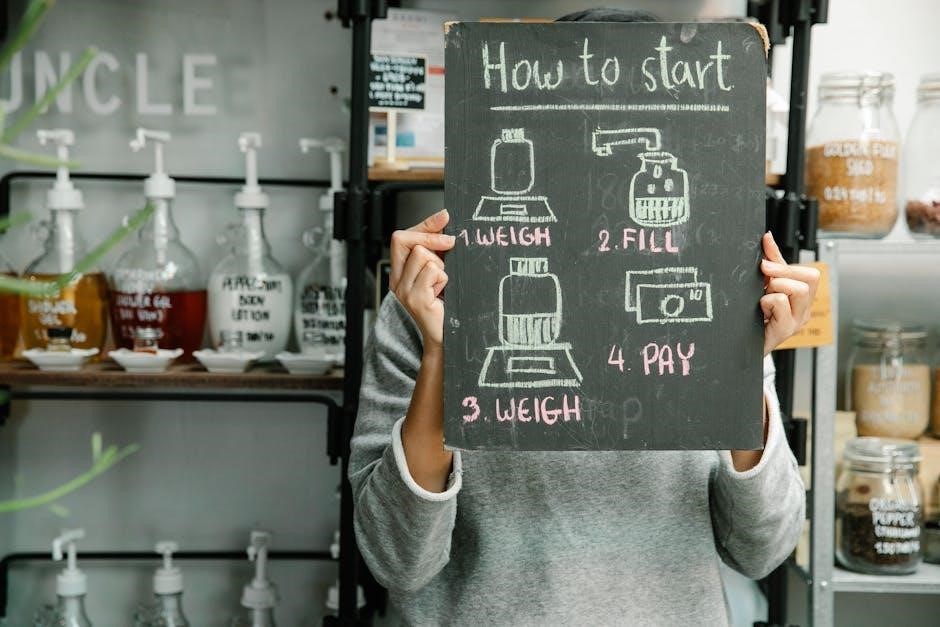

Step-by-Step Application Process

Apply Monobond Etch & Prime to the ceramic surface using a microbrush‚ gently agitating for 20 seconds. Allow the product to react for 40 seconds to ensure proper etching and silanization. Rinse thoroughly with water‚ then dry the surface completely. This streamlined process eliminates the need for multiple steps‚ making it both time-efficient and safe. The product is compatible with methacrylate-based luting composites and silicate-based glass ceramics‚ ensuring a reliable bond.

Recommended Contact Time and Rinse Procedure

After applying Monobond Etch & Prime‚ allow it to remain on the ceramic surface for 40 seconds to ensure effective etching and silanization. Rinse thoroughly with water to remove any residue‚ then dry the surface completely. Proper rinsing and drying are critical for achieving optimal bonding results. This streamlined process enhances safety and efficiency compared to traditional hydrofluoric acid etching methods‚ reducing handling risks and procedural time.

Advantages Over Traditional Methods

Monobond Etch & Prime streamlines ceramic surface preparation by combining etching and silanization in one step‚ eliminating hydrofluoric acid for enhanced safety and efficiency.

Comparison with Hydrofluoric Acid Etching

Monobond Etch & Prime eliminates the need for hydrofluoric acid‚ reducing toxicity risks and simplifying the process. Unlike traditional HF etching‚ it combines etching and silanization in one step‚ saving time and enhancing safety. HF etching is toxic and requires multiple steps‚ while Monobond offers a safer‚ more efficient alternative. This innovation improves bond strength and reduces manual errors‚ making it a superior choice for modern dental procedures.

Time Efficiency and Safety Benefits

Monobond Etch & Prime significantly enhances workflow efficiency by combining etching and silanization in one step‚ reducing procedure time. It eliminates the need for hydrofluoric acid‚ minimizing toxicity risks and handling of hazardous materials. This simplifies the process‚ reduces potential errors‚ and improves safety for both clinicians and patients. The streamlined protocol also allows for faster treatment‚ contributing to higher patient satisfaction and better clinical outcomes.

Compatibility with Dental Materials

Monobond Etch & Prime is compatible with methacrylate-based luting composites and silicate-based glass ceramics‚ ensuring reliable bond formation and versatility in various dental restoration applications.

Use with Methacrylate-Based Luting Composites

Monobond Etch & Prime is specifically designed to work seamlessly with methacrylate-based luting composites‚ such as those from the Variolink and Multilink product lines. Its unique formulation ensures a strong and durable bond between the glass-ceramic restoration and the luting composite. By integrating etching and silanization in one step‚ it simplifies the bonding process and enhances efficiency. This compatibility makes it an ideal choice for adhesive cementation‚ providing reliable results in various clinical applications while maintaining the integrity of both the ceramic and composite materials.

Suitability for Silicate-Based Glass Ceramics

Monobond Etch & Prime is specifically engineered for silicate-based glass ceramics‚ ensuring optimal surface preparation and bonding. Its advanced formulation reacts effectively with the ceramic surface‚ creating a strong chemical bond. This makes it highly suitable for use with all silicate-based glass ceramic materials‚ enhancing the adhesion of luting composites. The product’s ability to etch and silanize in one step eliminates the need for hydrofluoric acid‚ providing a safer and more efficient solution for dental restorations. Its compatibility ensures reliable and long-lasting results.

Troubleshooting Common Issues

Monobond Etch & Prime may face issues like inadequate bond strength or surface preparation problems if instructions are not followed. Proper application and rinsing are crucial for optimal results.

Addressing Inadequate Bond Strength

Monobond Etch & Prime may result in inadequate bond strength if not applied correctly. Ensure proper surface cleaning‚ correct application time‚ and thorough rinsing. Contamination or insufficient etching can compromise adhesion. Repeat the process if necessary‚ following the instructions precisely to achieve optimal results.

Resolving Surface Preparation Problems

Surface preparation issues with Monobond Etch & Prime often arise from improper application. Ensure the ceramic surface is clean and dry before applying. Avoid using excessive material‚ as it may lead to pooling. Agitate gently for 20 seconds and allow the product to react for 40 seconds. Rinse thoroughly with water and dry with clean air. Repeat if necessary to achieve proper etching and silanization for a strong bond.

Monobond Etch & Prime is a reliable solution for efficient ceramic surface preparation‚ offering a dual etching and silanization process. It ensures compatibility with methacrylate-based composites and enhances bond strength when used as instructed.

Monobond Etch & Prime is a single-component ceramic primer that combines etching and silanization in one step‚ eliminating the need for hydrofluoric acid. This makes the process safer and more efficient. It is compatible with methacrylate-based luting composites and silicate-based glass ceramics‚ ensuring a strong and durable bond. By simplifying the conditioning process‚ it reduces clinical steps and saves time‚ while its advanced formulation ensures a long-lasting and reliable bond between ceramic surfaces and resin cements.

Final Recommendations for Use

Monobond Etch & Prime is ideal for streamlining ceramic restoration protocols. Apply it with a microbrush‚ agitate gently‚ and rinse thoroughly after 60 seconds. Its compatibility with methacrylate-based composites and silicate ceramics ensures versatility. This product reduces clinical steps‚ enhancing efficiency while maintaining safety. For optimal results‚ always follow the instructions and use it as a replacement for hydrofluoric acid etching. This ensures a reliable and durable bond without the risks associated with toxic acids.